DRAINAGE CASE STUDY

Overview

Macari Hill Civil Engineering (MHCE) recently delivered a drainage package at a new mixed used Development, on the outskirts of Edinburgh. The works comprised of 160m of 225mm dia carrier/filter drain, Manhole construction and 25m of new foul sewer. In addition to this, the project remit also included remedial works to a pumping station which had been partially completed but was subject to severe water ingress. This case study highlights the details and challenges overcome whilst delivering this package of works.

Carrier/Filter Drain

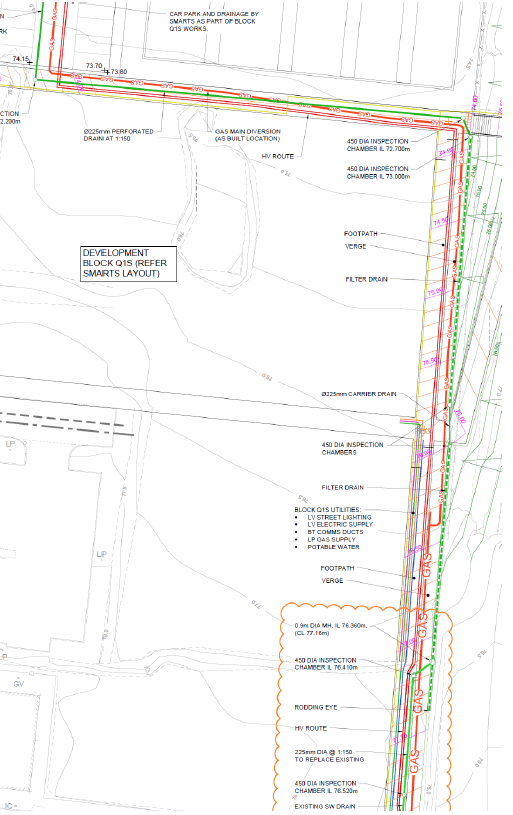

Installation During works to create a new marina, an existing surface water sewer was discovered which carried storm water from a nearby village. This drain needed to be diverted out with the curtilage of new development land. MHCE were tasked with installing the permanent diversion of this line as is shown in the fig. 1 below.

Fig. 1 Extent of new diversion in green

The new diversion comprised of both 225mm dia solid wall carrier pipe and 225mm perforated pipe within a filter trench. As well as the installation of 1200mm dia manholes at the start and end of the diversion, there were 4 no. 450mm dia catch pit inspection manholes installed on the line. The new diversion route needed to be constructed within the new services corridor. Due to the presence of a medium pressure gas main, which followed the same route of the storm water diversion, a substantial section of this needed to be hand dug (Fig.2)

Fig.2 Medium Pressure Gas Main within excavation.

Once the 225mm carrier drain had been installed adjacent to the marina wall, the 225mm dia filter drain was then installed towards the start of the stormwater diversion see fig.3.

Fig.3 Laying bedding prior to pipe installation.

This section of filter drain still followed the line of the gas main. A disused field drain also encroached the excavation for the storm sewer. The excess ground water from this was managed locally with a 2-inch sub pump.

Once at the tie in point, an inflatable stopper was used to block off the inlet to the exiting storm line. The existing flows were then over pumped, using a 3” pump, to the downstream manhole whilst the connection works were completed. The stopper was then removed, and the existing flows were permanently diverted.

Foul and Storm Sewer installation

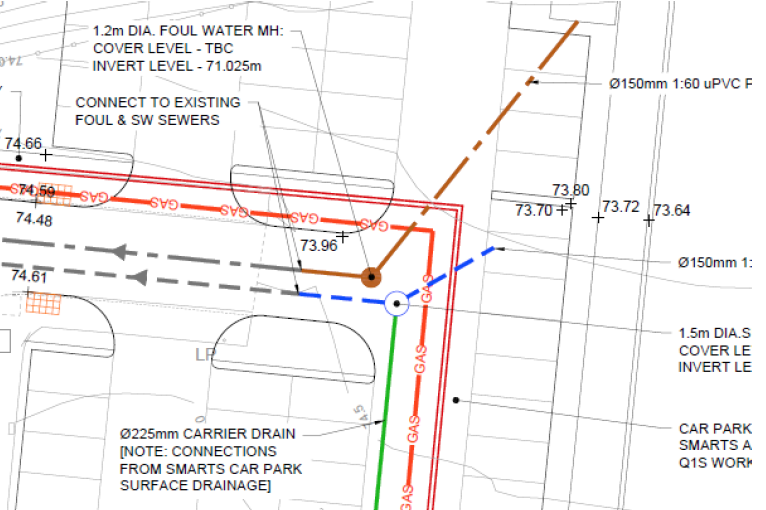

As part of the scope at Winchburgh, MHCE installed 25m of 225mm and 150mm dia foul and storm sewer. Part of these works comprised of the construction of a storm and foul manhole approximately 3.0m deep as well as installing tails from each manhole beneath the medium pressure gas main. See Fig.4

Fig.4 General layout of new foul and storm water sewer to be installed.

The client had originally asked for the new and existing storm sewer to be connected using a band seal. However, once the existing storm line was exposed and confirmed as being concrete, MHCE advised that a manhole would be more appropriate to join the concrete pipe to the UPVC pipe. A new 1200mm dia manhole was installed in this location.

Whilst excavating for the new foul manhole rock was encountered. This had to be broken out using a 20-tonne excavator with pecker attachment to reach invert level. Whilst doing this under pressure ground water entered the excavation. This was managed with pumps until concrete plug could be poured. The manhole was then constructed, and the excavation backfilled.

Fig.5 Pecker Attachment used to Break out rock.

Fig. 6 Rock being removed from Excavation.

Rock was encountered for the first 6m of the 150mm dia foul sewer installation. A Sheets and frames solution was used to install the 150mm dia sewer beneath the gas main. The standard trench box was then used to install the remainder of the pipe.

Pumping station remedials

MHCE were engaged to remediate and complete a wastewater pumping station which had been partially installed by a previous contractor. Winchburgh Developments M+E contractor could not commence their works until the chamber was fully sealed and the pumping station floor was in a condition which they could install their pumps and associated apparatus. Using their knowledge and experience, MHCE were able to quickly identify the source of leaking ground water to a poorly sealed inlet pipe to the pump well.

Fig. 7 Water ingress from underside of inlet pipe despite inflatable stopper being in place.

Fig. 7 Water ingress from underside of inlet pipe despite inflatable stopper being in place.

MHCE excavated down the outside face of the pump well and exposed the inlet pipe. A 4-inch hydrainer pump was then installed within a sump and used to lower the ground water level. The pipe was then inspected which confirmed that the stub pipe had not been sealed properly on the outside of the chamber. A shutter was then built, and concrete was poured and pokered ensuring a good seal to the pipe.

Once this had been completed the pump well was pumped out so the base could be inspected. This inspection confirmed that the previous attempt at forming the conical shape to the base of the pump well had not succeeded (fig.8). MHCE proceeded with breaking out the surplus concrete.

Fig.8 Surplus concrete to be broken out.

Once broken out, MHCE then poured the base of the pump well to the correct invert level. The base was then levelled off ready for the M+E contractor. MHCE then levelled and orientated the pumping station cover slab to ensure the M+E contactor could properly plumb and install the pump guiderails and duck foot bends on the base of the pump well.

MHCE then formed the 60° conical benching shape using S1 slump concrete and finished it with a 50mm thick granolithic finish. Once the pipe work was set and tested by the M+E contractor, MHCE shuttered the inside wall of the chamber where the pipework exits the well and poured concrete to seal the penetrations.

Fig. 9 Granolithic benching complete and pipe work installed.

Fig10. Cover slab set to correct orientation and pump guiderails installed.

Once the internal pump well works were completed by MHCE, the pump well was handed back to the client to finish the external works and commission the pumping station.